A significant explosion occurred at Accurate Energetic Systems (AES) in Hickman County, Tennessee, around 7:45 a.m. on Friday, October 10, 2025. The incident resulted in the tragic deaths of 16 workers and destroyed a building on the premises.

The force of the blast was so intense that it was felt several miles away, and debris was dispersed over a considerable area. Unfortunately, no survivors were located within the collapsed structure.

Company Profile

AES is engaged in operations at a large multi-building facility located near McEwen, Tennessee, where it employs a significant workforce dedicated to explosive processing, storage, and related activities.

Public procurement databases and reports indicate that AES has a history of managing substantial federal contracts involving the handling and assembly of energetic materials.

Rural Economy

The plant plays a crucial economic role in Hickman and Humphreys counties by offering specialized shift work, which is not typically available in the surrounding rural labor market.

Local and national media have reported on the region’s economic reliance on the plant and highlighted the immediate impact on households following the explosion.

Safety and Past Incidents

Regulatory records and previous reports indicate that the site has been subject to scrutiny by the Occupational Safety and Health Administration (OSHA) and has a history of incidents involving explosives.

Notably, there was a tragic blast in 2014 at the AES site that resulted in a fatality involving a lessee. These incidents contribute to the overall risk landscape associated with working with energetic materials.

What AES Does

State emergency officials have clarified that AES is involved in the processing of ammunition and explosives, rather than their manufacturing. This processing may involve tasks such as loading, assembling, and packaging energetic components that are obtained from external suppliers.

It is essential to note that, although AES does not manufacture these items, the processing activities can still result in production delays and bottlenecks, particularly if a facility experiences downtime.

Immediate Response

Sheriff Chris Davis described the incident as “one of the most devastating scenes” he has encountered in his career. Over 300 emergency responders were deployed to the location, and federal agencies, including the ATF, FBI, and TBI, became involved in the ongoing investigation.

Authorities informed residents that they may hear additional small explosions while response operations were conducted.

Investigation Status

Authorities have outlined that the investigation will be complex and could take days to weeks to complete, primarily due to the presence of hazardous materials, debris fields, and various safety constraints.

Multiple national news outlets have reported that the scene is being processed methodically, with a careful approach being necessary because of ongoing risks.

TNT Context in the U.S.

The United States hasn’t produced TNT since the 1980s and relies on imports for it.

The invasion of Ukraine has increased global demand and strained supplies, resulting in broader constraints on NATO-aligned production lines.

Domestic TNT Restart Plan

The U.S. Army has contracted Repkon USA to build a TNT production facility in Kentucky, marking the return of domestic TNT manufacturing for the first time in decades.

Public updates indicate that construction and commissioning will take 3 years before production starts.

AES and Procurement vs. Production

Contracts related to TNT typically involve activities such as procurement, handling, or integration of charges and components, rather than the actual manufacturing of TNT.

According to public contracting records and industry reports, AES plays a significant role in the processing and integration of these components, which is distinct from the synthesis of TNT itself.

Community Grief

AES leadership, along with local religious and civic groups, coordinated vigils and support initiatives for affected families.

Media coverage of these gatherings highlighted the community’s collective mourning and calls for assistance.

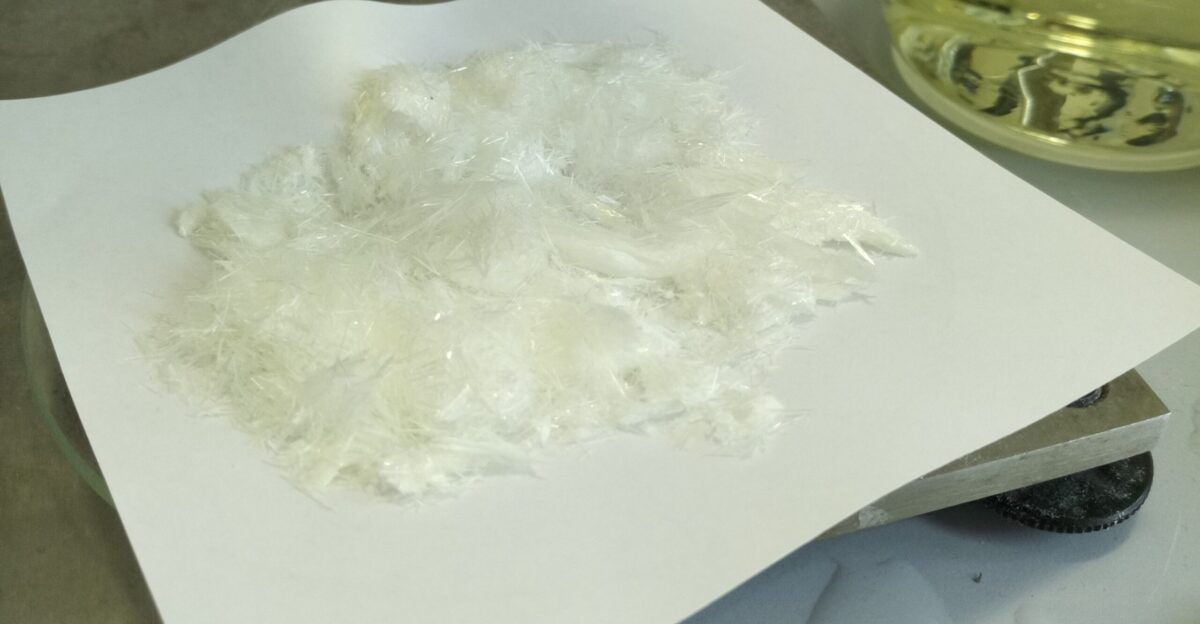

Hazardous Operations

Processing explosives necessitates strict adherence to protocols, comprehensive training, and the use of specialized equipment.

Documentation from companies and incident reports illustrates that this field carries inherent risks, which are meticulously evaluated by authorities following any incidents.

Military Dependence and Concentration Risk

The Pentagon relies on a mix of government-owned/government-operated, government-owned/contractor-operated, and private contractor facilities for energetics.

Shifts toward private-sector concentration and aging infrastructure have created fragility in key nodes.

Emergency Protocols and Public Safety

Officials communicated that while smaller secondary pops might be heard, the scene was secured against larger mass detonations.

Perimeters and traffic restrictions remained in place through the initial response period.

Political and Community Response

State and local officials reported a significant shockwave that was felt over a wide area, emphasizing both the impact on human lives and the necessity for a comprehensive investigation.

They cautioned against making sweeping policy changes without a thorough analysis of the situation.

Regional Benchmarks

Tennessee has a notable history of intricate industrial incidents. The coverage of the AES explosion was situated within a larger framework of risk management, environmental health, and the economic trade-offs encountered by rural communities that host hazardous operations.

This context highlights the significant challenges such communities face in balancing safety with industrial growth.

The Toll On Human Life

Authorities have reported a confirmed death toll of 16 individuals.

They are collaborating with the medical examiner’s office to facilitate the identification of the deceased and notify their families, a process that is proving to be challenging.

Global Supply Pressure

Since 2022, global shortages of TNT and energetic precursors have significantly impacted ammunition production in allied countries.

This situation has increased the strategic importance of bolstering domestic manufacturing capabilities and diversifying supply sources for these critical materials.

Technology Outlook

The coverage on defense-industrial and research initiatives emphasizes the commitment to adopting next-generation energetic materials.

These advancements aim to enhance performance and safety, with the potential to gradually decrease dependence on traditional TNT.

The Bigger Picture

The AES tragedy highlights three concurrent realities: persistent hazards in energetic-materials operations, a global supply shortage for TNT and related inputs, and the multi-year process of restoring domestic TNT production.

Mitigations include distributed processing networks, accelerated domestic capacity programs, and strengthened community safety investments.